Projects

We Build Plasma Solutions that Work in the Real World

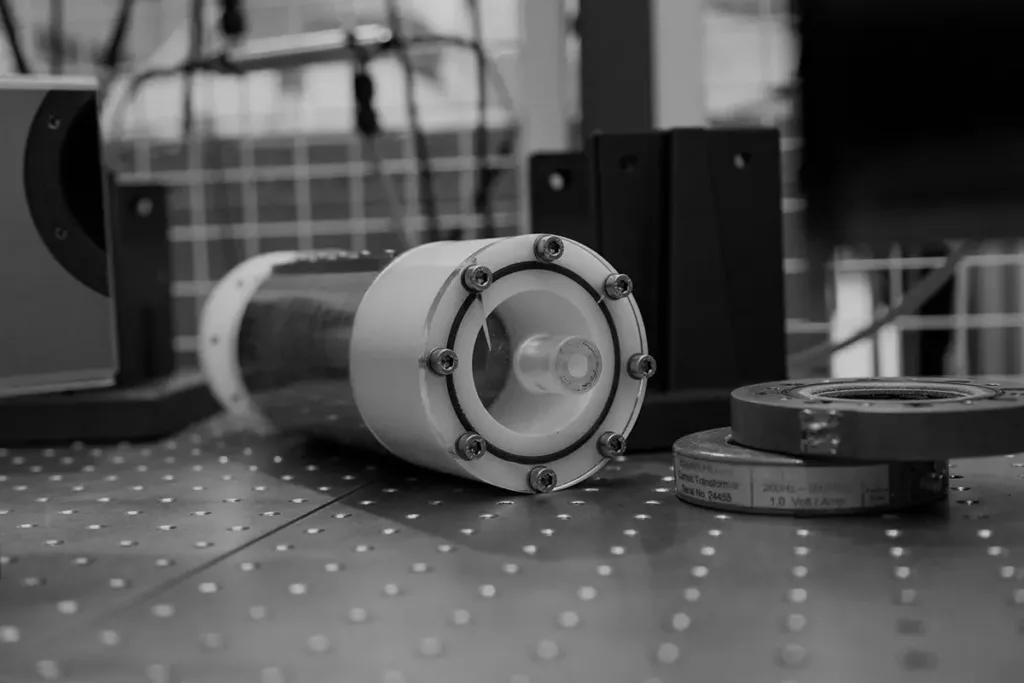

At KapiteinLabs, technology matters only when it functions outside the lab. That’s why we develop plasma-based solutions that are not just smart, but also scalable, energy-efficient, and directly relevant to today’s industrial and environmental challenges.

From air purification in greenhouses and factories to transforming CO₂ into valuable chemicals, our projects aim to expedite the sustainable transition through practical innovation.

In close collaboration with partners such as TU/e, CWI, ETH Zürich, Hitachi Energy, VitalFluid, and Royal IHC, and supported by NWO, the EU, and the province of North Holland, we connect science and its purposes. All our prototypes are tested in real-world settings to bridge the gap between potential and practice.

These pages provide an overview of our active projects, each unique in scope, but all driven by the same goal: to make plasma technology not only smarter, but truly instrumental.

Plasma for Clean Air

2021–2026

This OTP project scales up pulsed plasma technology for air purification in industrial and agricultural settings.

What it does

In partnership with TU/e-EES, TU/e-EPE, Botany BV, and Kuijpers Farmers, the project explores low-, medium-, and high-voltage plasma regimes to maximize purification efficiency. KapiteinLabs contributes by translating lab research into practical systems and overseeing real-world implementation.

Why it matters

By cleaning airflows in greenhouses, barns, and factories, plasma offers a scalable and non-chemical solution to improve environmental and human health, turning innovation into action.

Green Spark

2024–2029

This OTP project focuses on next-generation pulsed power systems for plasma applications.

What it does

In collaboration with TU/e-EES, TU/e-EPG, CWI, Hitachi Energy, and ETH Zürich, the project develops high-performance power electronics and investigates alternatives to SF₆ gas in high-voltage systems. KapiteinLabs plays a key role in translating advanced research into usable, scalable technologies.

Why it matters

By replacing one of the most potent greenhouse gases and enhancing plasma performance, Green Spark contributes to cleaner energy infrastructure and more effective plasma-based purification systems.

High Voltage on the Rocks

2025–2029

This Vidi project pioneers sub-nanosecond control in pulsed power systems for precision plasma applications.

What it does

KapiteinLabs collaborates with TU/e-EES, TU/e-EPG, VitalFluid BV, and INP to develop cutting-edge plasma control technologies. The goal is to achieve ultra-precise steering of plasma processes, unlocking new use cases in sectors such as healthcare, agriculture, and high-tech manufacturing.

Why it matters

This project, by achieving tighter control over plasma dynamics, paves the way for cleaner, more efficient, and highly targeted applications ranging from disinfection to material processing, thereby expanding the potential of plasma technology.

Plasma Toolbox

2024–2026

This JTF project develops a 10-kW pulsed plasma demonstrator for air purification.

What it does

With support from JTF IJmond and the European Union, KapiteinLabs and TU/e-EES are exploring solid-state pulsed power sources for energy-efficient plasma generation. The system is being tested and optimized in both TU/e labs and KapiteinLabs’ facilities to ensure real-world readiness.

Why it matters

By combining efficient plasma technology with practical testing, Plasma Toolbox brings clean air solutions closer to market, supporting health, sustainability, and industrial decarbonization.

CO₂ as a Resource

2024–2026

This JTF project explores how plasma can turn CO₂ from waste into value.

What it does

In collaboration with TU/e-EES and with support from JTF IJmond and the European Union, KapiteinLabs is developing a 10-kW solid-state pulsed plasma system that converts CO₂ into beneficial chemicals, such as CO or methane. The technology utilizes precise, energy-efficient plasma processes that do not rely on fossil-based inputs.

Why It Matters

Instead of simply storing CO₂, we convert it into a circular feedstock. CO₂ as a Resource contributes to a climate-neutral industry and helps regions transition away from fossil fuel dependence by generating value from emissions.